At Eurobike 2023, Ben Jones and Chris Deverson of Deviate Cycles gave us a preview of their prototype high-pivot downcountry bike made out of titanium and carbon – a motorcycle we now know because the Lowlander. The gorgeous frameset was produced as a part of Deviate’s exploration into how they will carry manufacturing to the UK at a value that’s aggressive with the Asia-made carbon frames.

Now, we be taught there’s a second prototype titanium bike from the Scottish model, aptly named the Tilander. It’s a 145mm journey high-pivot bike, very a lot primarily based upon the 145mm Highlander. Right here’s a more in-depth have a look at the Deviate Tilander, together with some perception into the Chilly Steel Fusion course of used to provide it.

Deviate Tilander Prototype

The Deviate Tilander is without doubt one of the most tasty titanium mountain bikes we’ve laid eyes on. Sadly, it isn’t out there to buy, and certainly it might by no means be. Its creation was one thing of a proof-of-concept, an early-phase prototype produced as a studying software for Deviate whose ambition, finally, is to fabricate frames within the UK.

At the moment, the Claymore and Highlander frames are produced in Asia from carbon fiber, however the model see a future the place some, or all, of their frames are produced from titanium within the UK, or extra particularly, Scotland. From a technological standpoint, it’s solely potential; there are many boutique manufacturers providing UK-made titanium frames, however prices are considerably astronomical.

There’ll at all times be a small portion of the market keen to pay the worth for titanium’s excessive strength-to-weight ratio, its isotropic properties and naturally, its strikingly stunning aesthetic. However, Deviate wish to do issues otherwise, producing titanium frames at a value aggressive with Asia-made carbon frames.

It’s a daring ambition. Working with titanium is infamously troublesome, requiring rather more tightly-controlled manufacturing circumstances than these wanted for metal or aluminum, and oftentimes tens of hours of handbook post-processing. These are two elements that contribute to the excessive prices often related to titanium bikes, to not point out the price of the fabric itself.

However, Ben and Chris from Deviate Cycles consider they might have stumbled throughout a extra economical, cost-effective methodology of manufacture. Admittedly, they aren’t wherever close to the manufacturing price they’re aiming for simply but, however forecasting that considers the scalability of the strategy suggests it’s actually not not possible.

How have been the Deviate Tilander and Lowlander produced?

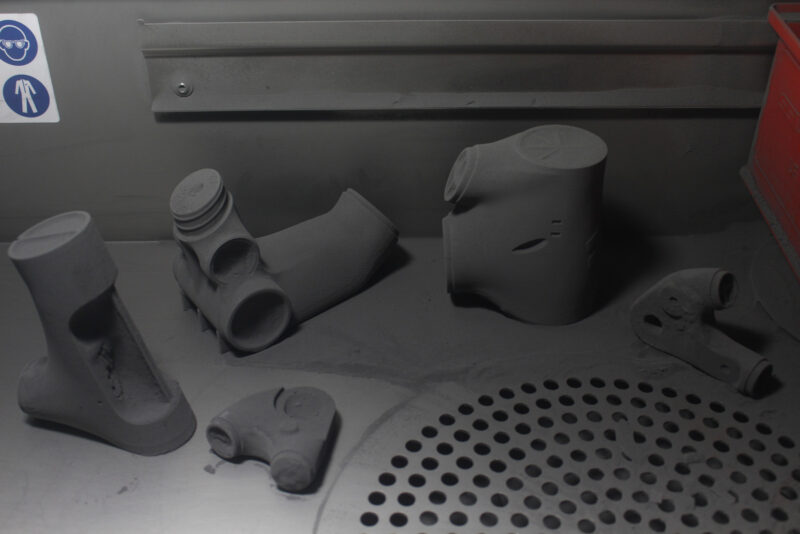

Their titanium lugs have been created through a technique of 3D printing known as Chilly Steel Fusion, or CMF. And, it’s executed by Element22, an organization primarily based in Germany that makes use of a course of developed by Headmade Supplies.

It makes use of makes use of a powdered type of titanium, every particle of which is coated with a polymer. The 3D printing course of melts the polymer, after which the sintering course of removes it whereas concurrently annealing the metallic. The strategy is claimed to provide titanium components which have round 97% the density of a machined block of titanium, and at a considerably decreased price.

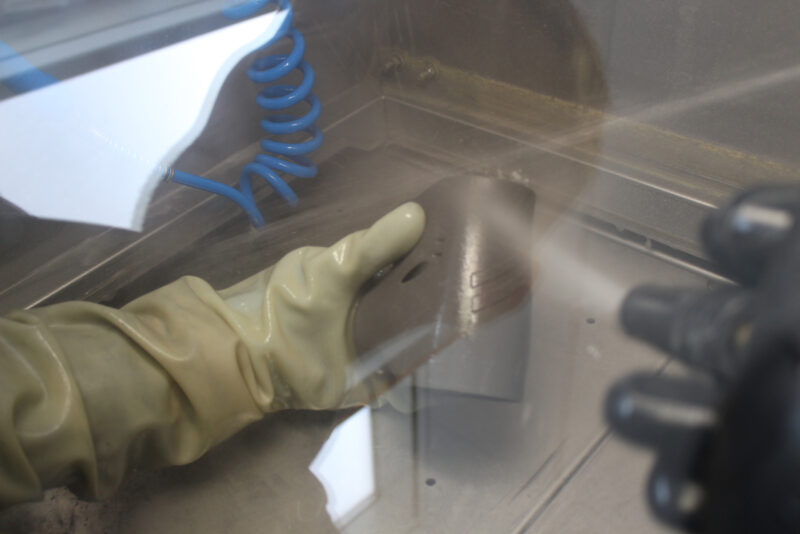

“The floor end is smoother, so we don’t must spend as a lot time ending. We will print these components floating in a powder mattress with no assist. We solely want minor helps to carry every little thing collectively through the sintering – earlier than we sinter it, the 3D printed half has roughly the feel of chocolate”

Johannes Schaper, Element22 Operations Supervisor

In fact, fewer helps additionally means much less waste.

Johannes is referring to the constructions which can be created together with the half that vital to carry it in place because it comes into being. You’ll be able to see examples of those constructions in this half-finished construct plate of Atherton Bikes titanium lugs.

“In relation to materials, we solely use what’s wanted. In aerospace they name it the “purchase to fly” ratio – we’ve a purchase to fly ratio of almost one, which is pretty much as good because it will get. We’ll have a tiny quantity of loss in free powder but when one thing goes unsuitable, we will truly reuse that free powder that we take off, and we will additionally reuse damaged components earlier than they’re sintered.” – Johannes Schaper.

Deviate’s efforts are actually to be applauded, however they’re wasted if the bike doesn’t trip properly. On this, Chris Deverson says, “Effectively, it’s stunning to trip a titanium bike, in fact and the Ti-lander acceleration response is completely not like the carbon body! There’s a sure spring to your inputs that’s troublesome to explain. Nevertheless it’s actually a superb feeling“.

We’ll be staying in contact with the blokes at Deviate to observe the evolution of Venture Tilander. In the meanwhile, you may observe their exploits on Instagram @deviatecycles.