On June fifteenth 2023, a patent filed by SRAM was printed to the USPTO database detailing a wi-fi chainring-integrated entrance shift mechanism for a 2x drivetrain. Therein, the standard entrance derailleur is changed by a shift equipment that’s fastened to the chainring itself, transferring because the chainring is rotated by means of every pedal stroke. That’s in nice distinction to generally obtainable entrance derailleurs which, with the notable exception of the Labeled Powershift Hub, are nearly completely fastened to the entrance triangle.

Let’s dig into the proposed workings of this entrance derailleur that’s housed totally on the crankset.

SRAM Chainring-Coupled Entrance Derailleur

Earlier than detailing how the chainring-coupled derailleur (for need of a greater identify) works, the SRAM patent in query (US 20200140035 A1) discusses a variety of drawbacks related to the present crop of entrance derailleurs. First up, as they’re nearly completely mounted to the seat tube, their mere presence forces constraints on body designers, stopping them from getting too inventive with body form for bikes which can be destined for a 2x drivetrain.

Then, there’s the shifting efficiency to think about. A conventional entrance derailleur consists of two metallic plates that push the chain inboard or outboard, guiding it to a bigger or smaller chainring of the crankset, respectively. The SRAM patent says that this mechanism may cause tough transitions, which may turn out to be problematic below very excessive masses.

Additionally, tying the shifting mechanism to the seat tube successfully makes the entrance triangle a key element of the shift equipment. If it flexes below excessive torque, or when the bike hits a bump within the street (assume Paris-Roubaix), the place of the entrance derailleur will transfer away from its good place relative to the chainrings, placing the system liable to misalignment with imprecise shifting because of this. I don’t actually understand how typically that situation truly causes challenge, however the authors of the SRAM patent noticed purpose to level this out.

SRAM suggest overcoming the aforementioned drawbacks with a brand new derailleur mechanism that {couples} the shifting system to the crankset itself. It reads, “The disclosed entrance shifting techniques shift easily and persistently, even whereas below heavy chain masses… [they are] simpler to put in and arrange than a standard entrance gear changer or derailleur and don’t require particular abilities or coaching”.

How does it work?

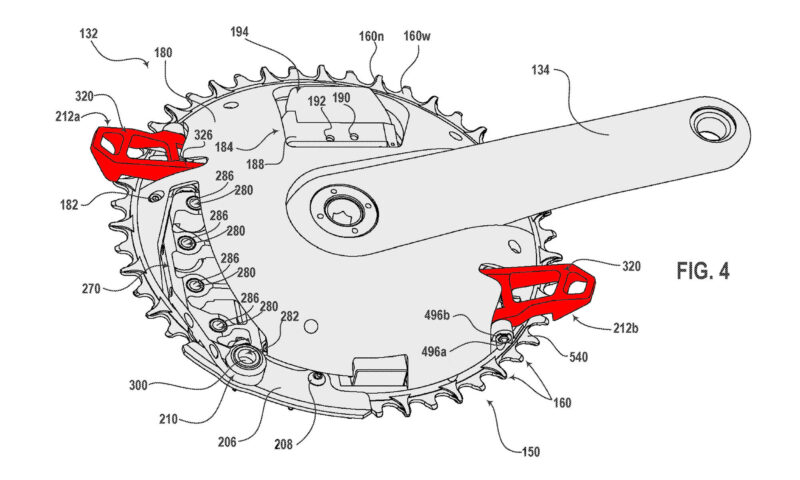

SRAM’s Chainring-Coupled Entrance Derailleur idea packs all the equipment essential to information the chain from the large chainring onto the small chainring, and vice-versa, into the the large chainring itself.

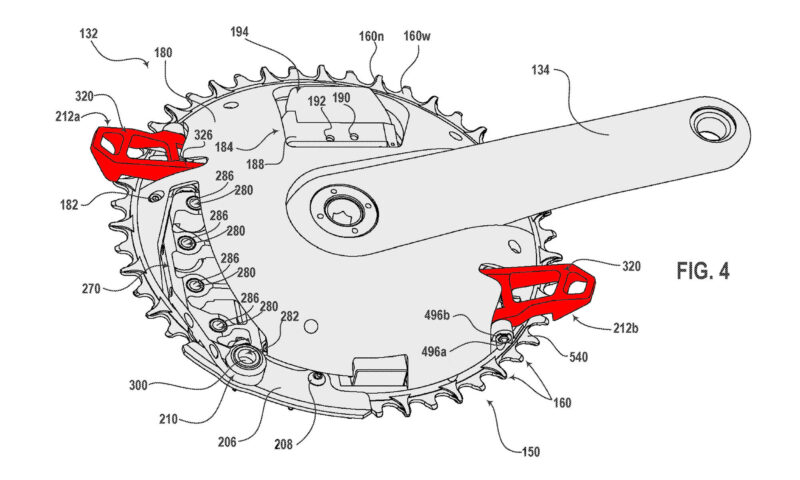

In a variety of the drawings, the inner workings of the distinct up-shift and down-shift elements are out of sight. They’re tucked beneath what the patent describes as an aerodynamic cowl that will additionally function a structural element that brings extra stiffness to the system.

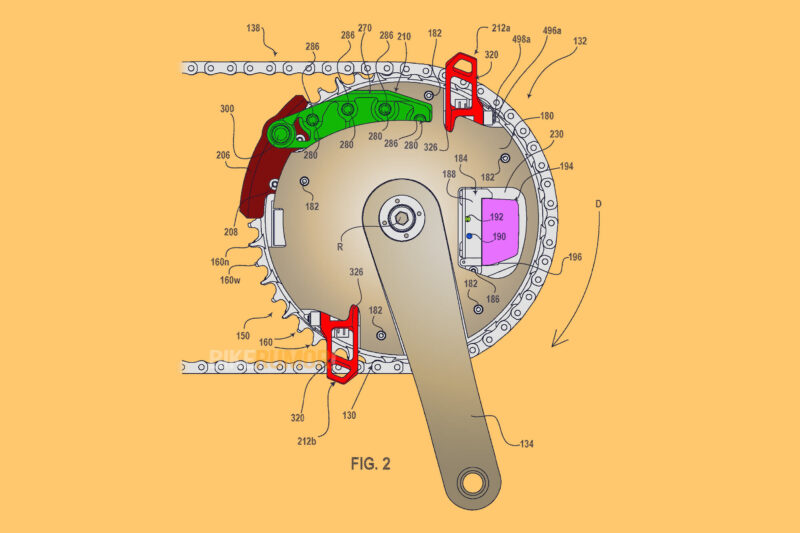

In fact, that is no mechanically-actuated shift mechanism. It is a wi-fi system, whereby up-shift and down-shift instructions are despatched from a bar-mounted distant – by way of Bluetooth or the like – to a receiver unit housed beneath that aero cowl. Accompanying the receiver is a detachable and rechargeable battery (purple) – that’s related in look to plain AXS batteries – a management unit, and a PCB. Seen externally, there’s a button for pairing the derailleur with the shifter (blue), and an LED that could possibly be used to point battery life (yellow).

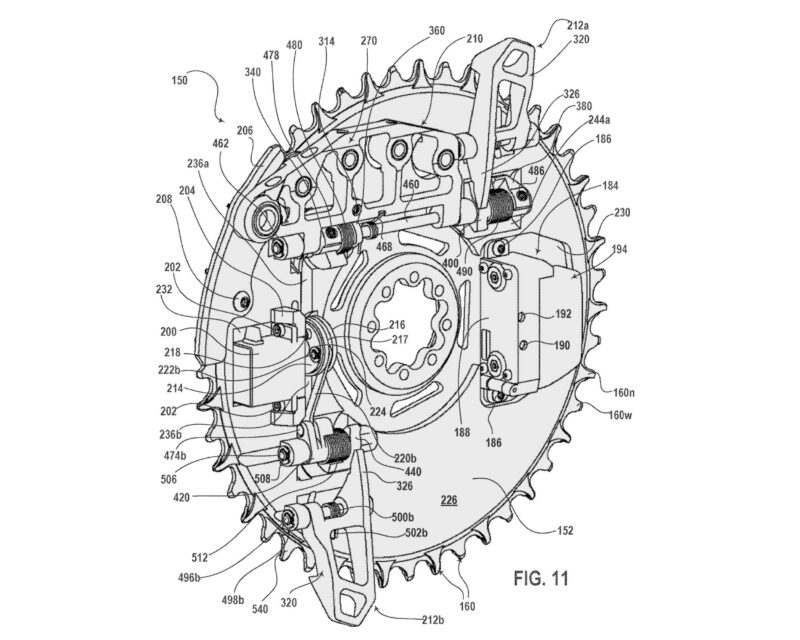

Additionally beneath that aero cowl is a motor and a collection of drivers, hyperlinks, shafts and pivots which can be rotatably related to 1 one other in such a approach as to power clockwise or counter-clockwise rotation of the up-shift and down-shift equipment (Fig. 11). We received’t concern ourselves with the intricacies of that, solely with the intricacies of how the chain is transferred from one chainring to the opposite.

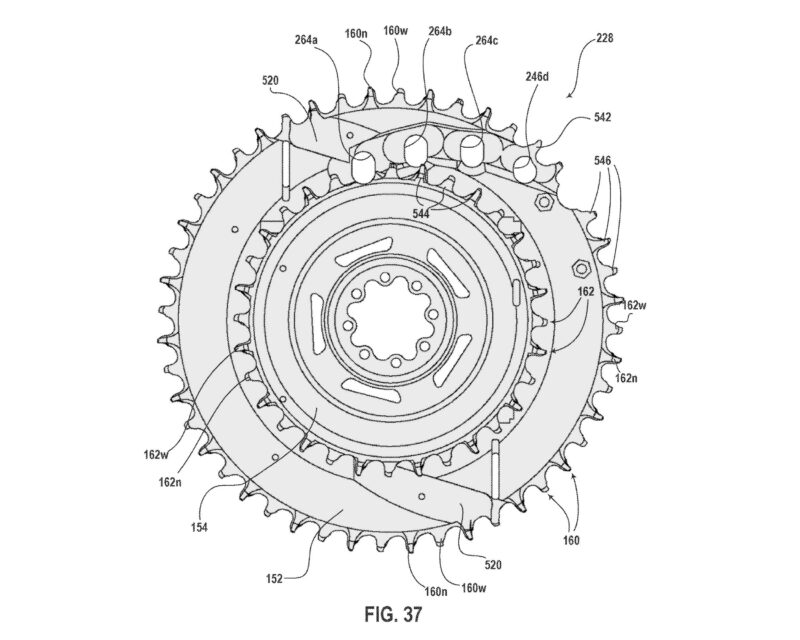

Earlier than we get began, take note of the structure of the chainrings proven in Fig. 37 (above). Right here, the chainrings are proven with out the chain or any of the shifting equipment connected. The buildings labelled 264a-d are literally holes that enable for protrusion and retraction of the up-shift equipment (seen in inexperienced in later photos). And, very importantly, each the large chainring and small chainring seem like lacking one tooth, one other attribute that’s important to the workings of the up-shift mechanism, as will turn out to be clear.

Onward, and upward…

The Upshift Mechanism

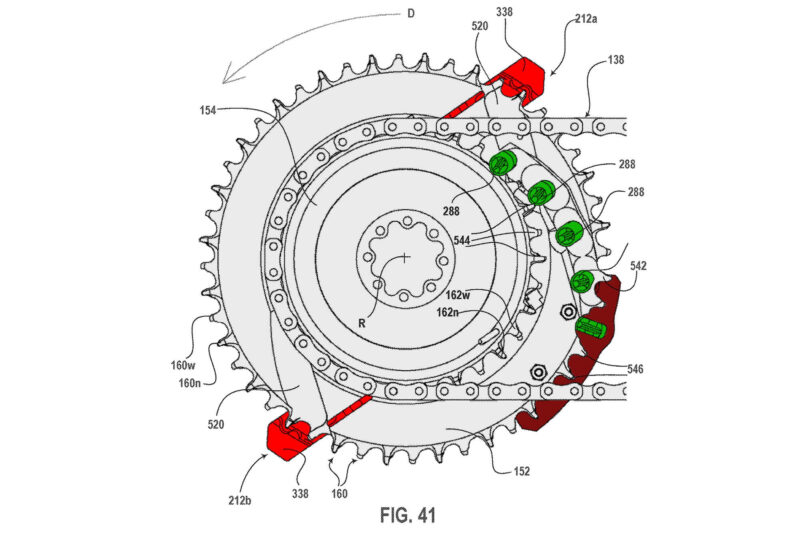

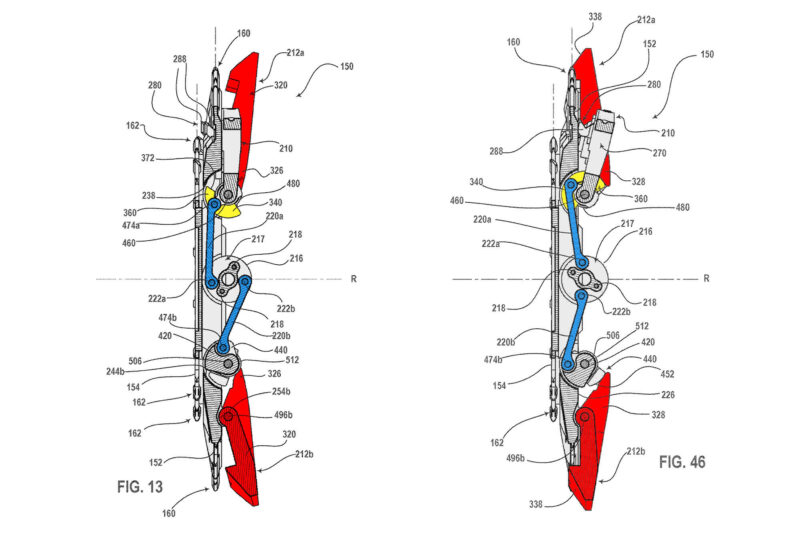

Right here, we’ll delve into the up-shift mechanism; how the chain is transferred from the small chainring to the large chainring. To kick off this rationalization of the up-shift mechanism, we’re going to counter-intuitively begin by wanting on the parts of the downshift equipment – 212a and 212b, proven in purple.

When the chain is operating on the small chainring, these two hooked arms are positioned excessive of the large chainring, taking over the house that the chain will accomodate as soon as the up-shift is full. So, it is sensible that the up-shift begins with the outboard rotation of those downshift parts away from the enamel of the large chainring.

The up-shift driver (yellow), and its connecting hyperlinks (blue), are proven clearly in Fig.13. Because the up-shift driver rotates counter-clockwise, the hyperlinks of the mechanism pull the arms of the down-shift parts by means of a clockwise arc, re-positioning them away from the enamel of the large chainring. That’s step one, which is subsequently adopted by the inboard rotation of the up-shift equipment (inexperienced)… however solely when the timing is correct.

The up-shift equipment (inexperienced) is simply allowed to fall inwards, slotting the information pegs (inexperienced) by means of the complementary holes of the large chainring, when the chain is evident of these holes, i.e. when the chainring has been pedaled right into a place whereby the up-shift equipment is in a rearward place, as proven in Fig. 41.

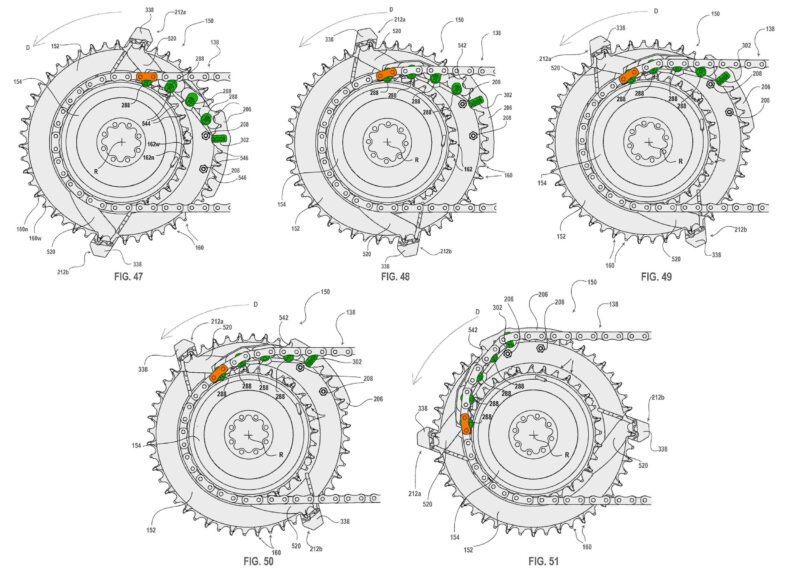

From right here, the sequence of occasions is sort of intuitive (under, Figs. 47-51). In all the drawings, the small chainring seems to be lacking a tooth. That house is stuffed by the primary information peg of the up-shift equipment (inexperienced) when it rotates inboard. From right here, it is ready to catch maintain of the chain, by way of the interior floor of an outer plate, as it’s pulled by means of the pedal stroke.

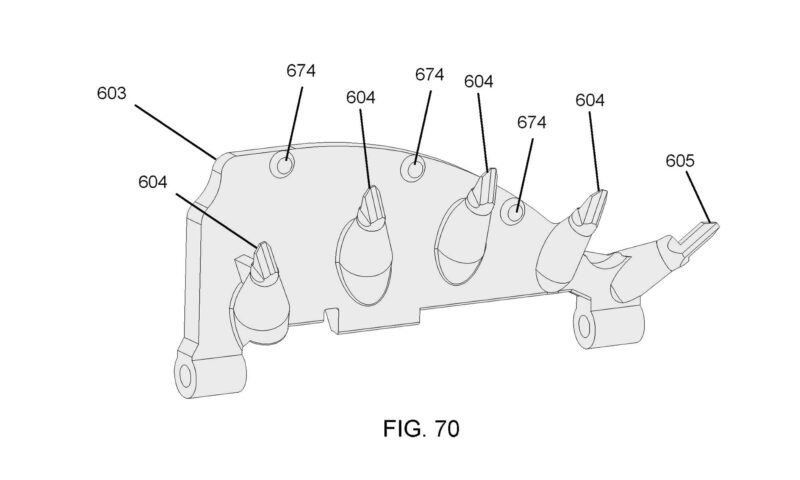

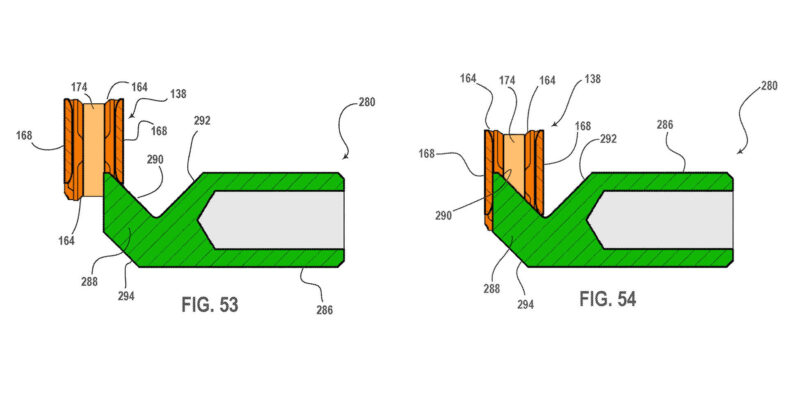

Fig. 70 reveals how every information peg is strategically positioned such that every subsequent one sits barely additional outboard (radially) than its neighbor. The anatomy of these information pegs is vital to the up-shift mechanism. Figs. 53 & 54 present how every peg (inexperienced) has a tip with a chamfered prime floor (290) that enables the chain to slip down the peg, pulling it additional outboard because it slides.

Through the sequence seen under in Figs. 47-51, the outer plate of the chain hyperlink (orange) that originally contacts the primary information peg is progressively moved away from the airplane of the small chainring, and into the airplane of the large chainring, with a ultimate, bigger up-shifting peg finishing the transition. That up-shifting peg (320) then stays in place, thereafter functioning as a daily tooth of the chainring. The massive plate (206, burgundy in some drawings) that sits outboard of the large chainring enamel acts as a information to forestall the chain falling off the large ring within the outboard path throughout an up-shift.

The Downshift Mechanism

Now, we take a better take a look at the down-shift mechanism of SRAM’s chainring-coupled entrance derailleur, whereby the chain is transferred from the large chainring to the small chainring. This mechanism just isn’t so completely different to how conventional seat-tube mounted entrance derailleurs information the chain off the large chainring towards to airplane of the smaller chainring.

To mediate a down-shift, the linkage controlling the positioning of the down-shift parts (212a and 212b in Pink) articulates about its varied pivots as a way to rotate the down-shift parts by means of a counter-clockwise arc. It strikes from the place proven in Fig. 13, to the place proven in Fig. 46, re-positioning the protruding arms of the down-shift parts inboard, to the purpose the place the highest floor (338) overlaps the airplane of the large chainring.

Along side this rotation, the information pegs of the up-shift equipment are concurrently retracted away from the small chainring and again right into a devoted recess inside the physique of the big chainring.

Once more, the timing is essential. A down-shift aspect will solely have the ability to rotate into the place proven in Fig. 46 when it’s positioned rearward of the chainring. i.e. at a place the place the chain just isn’t engaged with the enamel of the large chainring – see Fig. 52. That’s as a result of the presence of the chain on the enamel will bodily forestall motion of the down-shift arm into its down-shift place.

When the downshift arm is free to rotate inward to a place the place it overlaps the airplane of the large chainring, it’s then able to de-rail the chain off the large chainring. Because the rider continues by means of the pedal stroke, the chamfered floor (338) of the “main” down-shift arm (212a) contacts the chain, deflecting it out of alignment with the large chainring, and into alignment with the small chainring.

After not more than half a pedal stroke, the chain is picked up by the small chainring. After a full revolution, all hyperlinks of the chain will likely be engaged with the enamel of the small chainring, and the down-shift is accomplished.

Is the SRAM Chainring-Coupled Derailleur an Trade First?

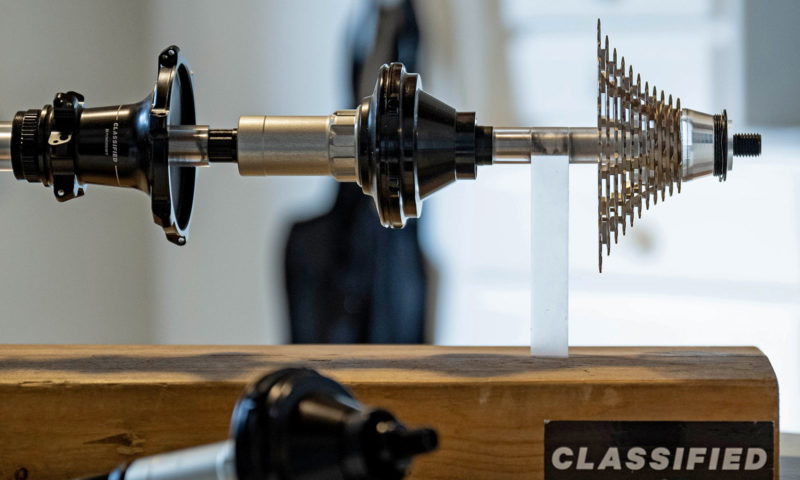

SRAM is under no circumstances the primary model to research alternate options to the standard, seat tube-mounted entrance derailleur. Labeled Biking provide probably the most strong, confirmed answer with their Powershift Hub. By advantage of inner gearing packed away contained in the hub of the rear wheel, the Powershift Hub is ready to provide two distinct gear ratios for each single sprocket of the cassette. So, should you’re operating a 12-speed cassette, you even have 24 discrete gears at your disposal.

Truly, this isn’t even the primary time we’ve seen an organization try to combine the entrance shift mechanism into the chainring-crankset meeting. Vyro, an organization that’s seemingly not in existence, tried to deliver one thing much like market in 2015.

The Vyro Am En1 cranks, aimed toward All-Mountain and Enduro functions, featured a giant chainring that was successfully segmented into 4 quarters, every capable of transfer radially outboard independently of each other as a way to enable the chain to fall from the large ring to the small ring because the rider pedaled the cranks by means of a full rotation. It was a neat answer that allowed the rider to shift below load, however in apply there have been some actual points with its sturdiness, and our EU Tech Editor, Cory Benson, had the misfortune of some key element failures whereas testing the system.

Potential Implications for a Entrance Derailleur That Lives on the Chainrings

The answer proposed by SRAM is sort of completely different to the abovementioned designs, but nonetheless claims to supply higher shifting below load than a standard seat tube-mounted entrance derailleur. And, it ought to enable body designers the liberty to re-shape the entrance triangle within the data they not want to supply a structural member for the mounting of it.

For some uncommon body designs, just like the Rondo Ruut 2.0 and the 2023 Specialised Sirrus, the implications are clear. Whereas their lack of a suitably-positioned seat tube presently prevents them benefiting from a two-chainring crankset, SRAM’s chainring-coupled derailleur appears to be an affordable answer.

There may be additionally scope right here for a giant enchancment within the aerodynamic properties of the drivetrain as a complete. Depending on how well-executed that aerodynamic cowl for giant chainring is, this might lead to markedly lowered drag as in contrast a entrance derailleur clamped onto the seat tube the place it is vitally uncovered, with the wind hitting it from all angles.

Definitely, there appears to be some good arguments for this new entrance shifting mechanism. On prime of these already talked about, this technique would certainly be a lot simpler to arrange than a standard drivetrain, wouldn’t it? That stated, we additionally foresee a variety of downsides.

First up, shifting in both path is more likely to be slower than the shifting enabled by present entrance derailleur designs. Per revolution of the crankset, just one alternative is supplied for an up-shift, with two alternatives supplied for a down-shift.

So, depending on cadence, the rider may expertise a noticeable lag in shift initiation as they look ahead to the shift equipment to hit the appropriate level within the pedal stroke. That compares to common entrance derailleurs that may provoke a shift on demand, the place the lag is successfully depending on the ramps and pins of your chainrings, typically offering 3-5 shift factors per rotation on premium drivetrains.

Additionally, it seems as if it could be very tough to execute a modular model of this technique whereby chainring sizes may be switched as much as the rider’s choice, and the gradients and elevation profiles in several components of the world. We reckon the up-shift mechanism not less than will likely be distinctive to a particular pairing of chainring sizes. That’s in distinction to the present crop of entrance derailleurs which provide a point of adjustability to go well with completely different chainring sizes and mixtures.

Then, there’s the query of sturdiness. As proven, giant parts of the up-shift and down-shift mechanism will likely be uncovered to moisture, in addition to grime and dirt from the street floor. That’s the case with any derailleur after all, however this mechanism does characteristic numerous pivots which can be all liable to untimely put on if the system isn’t sufficiently sealed.

Additionally, these down-shift elements are going to see a substantial quantity of grime kicked up from the entrance tire by means of each single rotation of the crank, and I don’t think about any of will probably be a stroll within the park to wash.

Lastly, I do marvel how Q-Issue could be impacted by the housing of all that infrastructure on the large chainring. It appears attainable the design may require a barely wider Q-Issue, which can be an undesirable characteristic for some riders.

Equally, for these liable to heel rub points, the extra actual property packed beneath an outboard cowl on the chainring may pose additional challenge with clearance all through the pedal stroke. Definitely, the clocking of the elements and their packaging would want to think about this very fastidiously.

Hypotheses apart, we’ll not be ready to totally perceive any of the above until SRAM can, and even need to, execute on this design.

We’ve reached out to be taught of their plans for this new shifting know-how, however it’s a “no remark” for now. In fact, a patent serves solely to guard the inventors’ concepts from implementation by opponents; it doesn’t imply SRAM truly plan to deliver this chainring-coupled entrance derailleur to market, nor does it essentially imply they also have a working prototype.

I’m prepared to wager they do, although. We predict it is a cool concept from SRAM, and wouldn’t be shocked in the event that they finally introduced this, or one thing very related, to market over the following few years. Even when it by no means sees the sunshine of day, it’s at all times tremendous fascinating to see what the brains behind the large manufacturers are engaged on behind the scenes.